Apprenticeships

Get Paid While You Learn

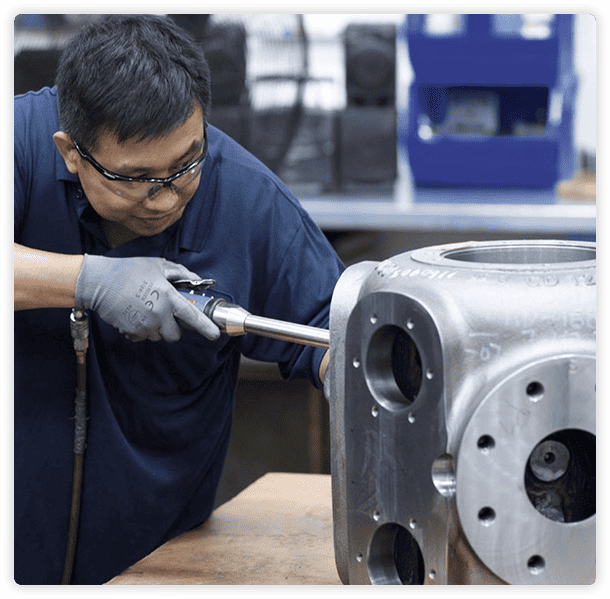

Manufacturing apprenticeships are a valuable opportunity for individuals to gain hands-on experience and training in the manufacturing industry while also earning a wage.

By participating in an apprenticeship program, individuals can learn from experienced professionals, develop technical skills, and build a strong foundation for a career in manufacturing. We encourage individuals who are interested in pursuing a career in manufacturing to consider an apprenticeship program in the West Ohio region.

Earn & Learn

To build Ohio’s manufacturing talent pipeline, WestCOMP is a member of the Ohio Manufacturing Workforce Partnership (OMWP), a statewide initiative to upskill 5,000 Ohioans through innovative work-and-learn (apprenticeship) strategies. The program is funded by a $12 million, four-year U.S. Department of Labor grant.

Ohio Manufacturing Workforce Partnership

Apprenticeships

The West Central Ohio Manufacturing Partnership (WestCOMP) serves to promote career training in the manufacturing trades. In this role they lead a group of manufacturers to recruit, screen, hire and train apprentices. This type of apprenticeship model allows for a streamlined approach to the administrative responsibilities associated with apprenticeships. Occupations that are part of this group sponsored model program are machinists, industrial maintenance and welding, and production operators. For information about this apprenticeship grant contact Lew Modic (modic.l@rhodesstatecollege.edu).

See www.industryneedsyou.com for more information on apprenticeships.

Approach

Promote collaboration and resource sharing among manufacturers and their education and workforce partners through regional sector partnerships.

WestCOMP is part of Ohio’s statewide network of regional sector partnerships that provide forums for manufacturers to identify shared workforce challenges that can more effectively be addressed collectively rather than as individual companies. Manufacturers work with area education and training providers to develop relevant training programs to maximize efficiency in developing talent in, initially, these in-demand skill areas:

- Production

- Machining

- Welding

- Industrial maintenance

- Automation and robtics

Develop

New programs will adopt the best elements of traditional apprenticeship programs while giving manufacturers the flexibility to focus on skills and outcomes most important to their success. Businesses can decide what works best for them while providing work-and-learn programs that include:

- Paid, work-based learning delivered by the employer

- Structured, on-the-job training and mentorship

- Technical instruction relevant to approved apprenticeship pathways

- Completion of a nationally portable, industry-recognized credential

- Standards for safety, supervision and equal opportunity

- Educator externships

Ensure career readiness by connecting training to specific industry-recognized credentials.

Work-and-learn programs give employees specific skills they need to be effective in today’s modern manufacturing. An industry-recognized credential is a third-party verification of an individual’s competence and can take many forms, including certifications, certificates, licenses and degrees.

Credentials also align to well-defined career pathways for employees. This is especially attractive to workers who desire a long-term development strategy, especially young people. This can be key to long-term retention.

Work-and-learn strategies will be a central focus as we address the workforce challenge in the West Central Ohio. For more information, contact Lew Modic, Project Manager, Rhodes State College.